Plastic CNC machining is the process of shaping plastic material blocks using a CAM program and cutting machines. Different techniques, including turning and milling, are employed to achieve plastic machining. This manufacturing approach enables the production of intricate components with a high degree of precision, all within a condensed period, ensuring superior quality.

Plastic CNC machining offers a distinct advantage for prototyping and producing small batches. Unlike methods such as injection molding, this process doesn’t necessitate the creation of molds, making it a swift and efficient choice with minimal lead times.

Plastic CNC machining achieves an unparalleled level of dimensional accuracy, surpassing what may be attainable through alternative methods like 3D printing.

By selecting plastic materials that closely resemble those used in mass production, it becomes possible to meticulously verify properties such as heat resistance and strength during the prototype phase. This validation mirrors the conditions of full-scale manufacturing.

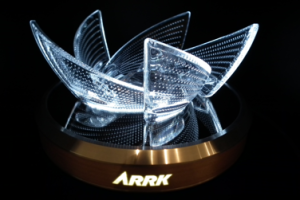

At ARRK, we have a strong advantage in plastic CNC machining. We have a wide-reaching network that helps us meet various needs effectively. Our skilled craftsmen are great at making high-quality plastic parts, especially those with complex shapes and advanced machining techniques. We’ve gained a lot of experience from working on design models, which allows us to provide excellent surface finishes and treatments with great accuracy.

Maximum Machining Size

Undercuts, Sharp Edges

Micro Machining

At ARRK, we offer a variety of resin materials based on our customers' needs and purposes.

• ABS (Acrylonitrile Butadiene Styrene) • PMMA (Polymethyl Methacrylate, commonly known as Acrylic) • PC (Polycarbonate) • POM (Polyoxymethylene)For other handled materials, please feel free to reach out for consultation.

Q:Can complex designs be machined in a single process, even for intricate details?

A:Absolutely, at ARRK we employ advanced 5-axis machining to achieve complex designs in a single operation.

Q:How can I obtain prototypes using production-grade materials?

A:ARRK offers a solution by crafting material blocks from your production-grade choices and utilizing CNC machining. We can also suggest alternatives like microwave molding or simplified molds.

Q:Will delicate structures be retained even with thin walls?

A:To ensure precision, we initially create partial samples for validation prior to commencing CNC machining.

For More details contact us