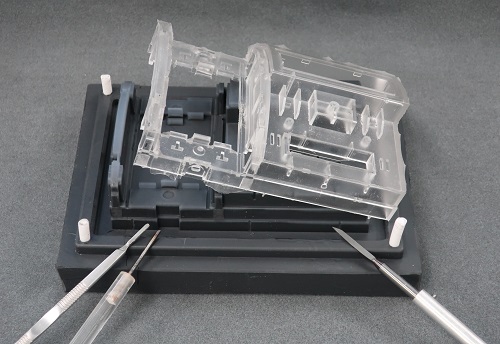

Microwave molding involves filling pellets into a specialized silicone rubber mold, closing the mold with a vacuum seal, heating it using the principles of a microwave oven, and melting thermoplastic resin to form the desired shape. After sufficient cooling, the molded product is removed from the mold. The manufacturing process is similar to injection molding, but the types of resins used differ: injection molding employs “thermosetting” resins, while microwave molding uses “thermoplastic” resins.

By creating prototypes using production materials, it’s possible to conduct property evaluation tests similar to those in mass production. This method offers significant cost reduction compared to simple injection molding. The silicone mold can be manufactured in a short period, enabling a shortened lead time.

While microwave molding has long been considered unsuitable for practical applications, ARRK’s advanced molding techniques have made it a viable market option. Leveraging expertise in silicone molds, we perform optimal mold design, allowing for the reproduction of properties close to those of mass-produced materials. We have numerous achievements in the field of developmental materials as well.

We support various materials, including but not limited to:

• ABS

• PP

• PC

• Transparent PMMA

• POM

• Talc-reinforced PP

• Other materials beyond those listed are also compatible.

However, depending on the shape and material, there might be cases where compatibility is challenging. Please reach out to us to discuss your specific needs.