A Rewarding Challenge: Taking On a High-Difficulty Project

We received a request from Panasonic Corporation to manufacture a model of an EV commuter vehicle for their 100th-anniversary celebration event. While they had a vision to introduce a new form of mobility to society, our team had limited experience in manufacturing operational commuters. Initially, we felt that meeting the demanding requirements of our client would be a formidable challenge.

We had to design a vehicle that adhered to weight limitations and ensure its completion within the tight timeline leading up to the event. Doubts surfaced about whether the vehicle would perform flawlessly during the event. Nevertheless, our team was highly motivated to leverage our creativity and technical expertise to surpass the client’s expectations, and thus, the project began.

Venturing into Uncharted Molding Methods

Given the high level of difficulty and the tight timeframe (approximately four months), we assembled specialized teams for each stage of the project and formulated a coordinated plan of action.

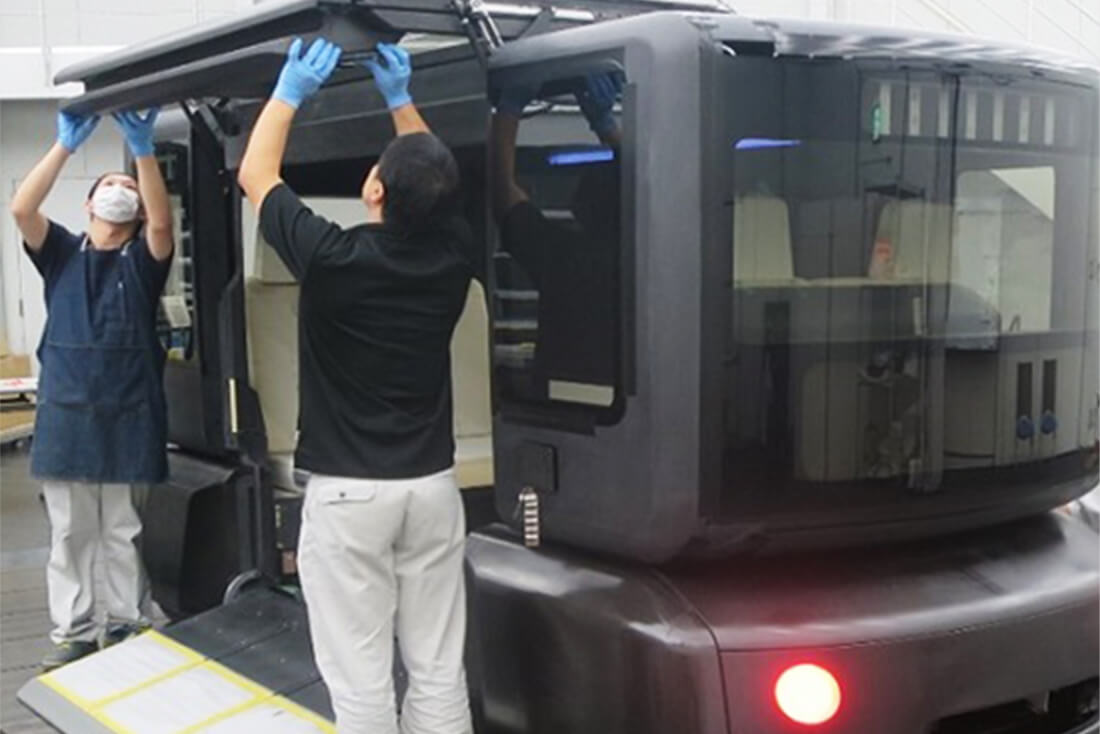

The event would require the commuter vehicle to carry general attendees and perform unmanned driving both forwards and backwards. Ensuring unprecedented levels of safety and durability became a paramount challenge. Of particular concern was the design of the vehicle’s doors, which featured an upper lift-up style and a lower ramp style. Integrating mechanical components and motors into the relatively thin door openings of the vehicle proved to be a significant challenge.

Additionally, the power unit needed to comply with the client-supplied motor’s specifications, with a target weight of under 1600 kg when unoccupied. Our team dedicated considerable effort to achieve this goal.

Furthermore, we opted to use dry carbon molding, a technique commonly used in racing vehicles, for the cabin, door panels, and exterior panels. However, this was our first time extensively using this method, making it a learning process. Despite these challenges, we insisted on producing the cabin’s front and rear sections using dry carbon in a monocoque structure, successfully keeping the weight just under 1400 kg.

Exceeding Expectations with Innovative Door Mechanisms

Throughout the design phase, we maintained close communication with the client, thoroughly addressing their specifications and requirements.

The days leading up to the start of manufacturing were filled with tension, as we carried the responsibility of completing the design. There were concerns about whether the dry carbon monocoque cabin, outsourced to another party, would be completed as per our design. Despite these challenges, a well-defined delegation of roles, including sales, project leadership, production management, and various production departments, allowed each team member to proactively contribute. Our efforts paid off, and we successfully engineered the seats to move electrically according to the client’s content, ensuring that the commuter vehicle met the client’s demands despite its high level of difficulty.

Regarding the challenging door mechanism, although there were instances where post-delivery maintenance was necessary, we take pride in achieving a functional opening and closing system under tight constraints and incorporating high safety standards. This aspect was likely appreciated by the client.

An Indispensable Partner in Shaping the Future

We were fortunate to participate in two consecutive years of extremely challenging projects that aimed for the future. Not only did we realize our desired objectives, but we also received valuable proposals from ARRK. We successfully delivered a meticulous and highly precise model. ARRK is an indispensable partner for shaping the future. We look forward to continued collaboration in the years to come.

Panasonic Corporation, Automotive Company, Development Division, Mr. Usui

製品開発に関するご相談はアークまで

お問い合わせはこちらから